MILIN SALES CORPO.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MILIN SALES CORPO.

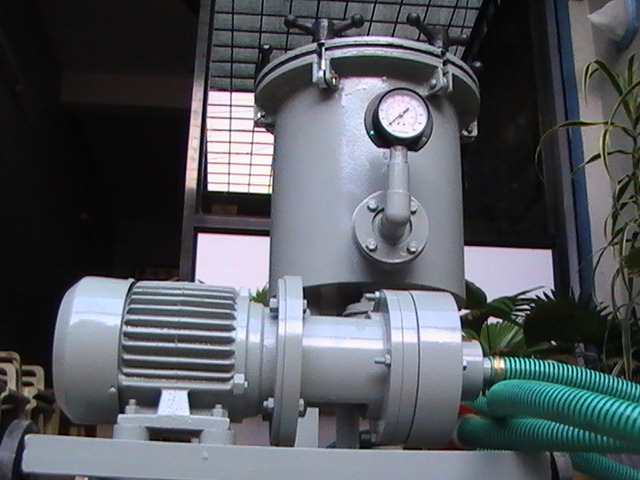

Turbine Blower

The turbine blower is a non-positive displacement, high volume, high pressure, blower that can operate as either a compressor or a vaccum pump. It is also knows as other names such as regenerative blower, vortex blower and side channel blower. All of the names describe the basic principle of operation of the turbine blower.

The blower consist of a strong impeller mounted directly on a motor shaft and is rotated at very high speed of about 2900 R.P.M. On the periphery of the impeller is large number of radial blades. The impeller is positioned between two end plates and with the blades located with a channel on either side.

The turbine blower is also known as an ineffective multi stage compressor with each of the regeneration of the air becoming another stage.

The basic construction of a turbine blower means that the only moving part is the impeller and nothing else touches except bearings. The method of compression means that there is now requirement for lubrication and on the compression chamber. The discharge of air is oil-less. The blowers should be mounted vertically or horizontally

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.